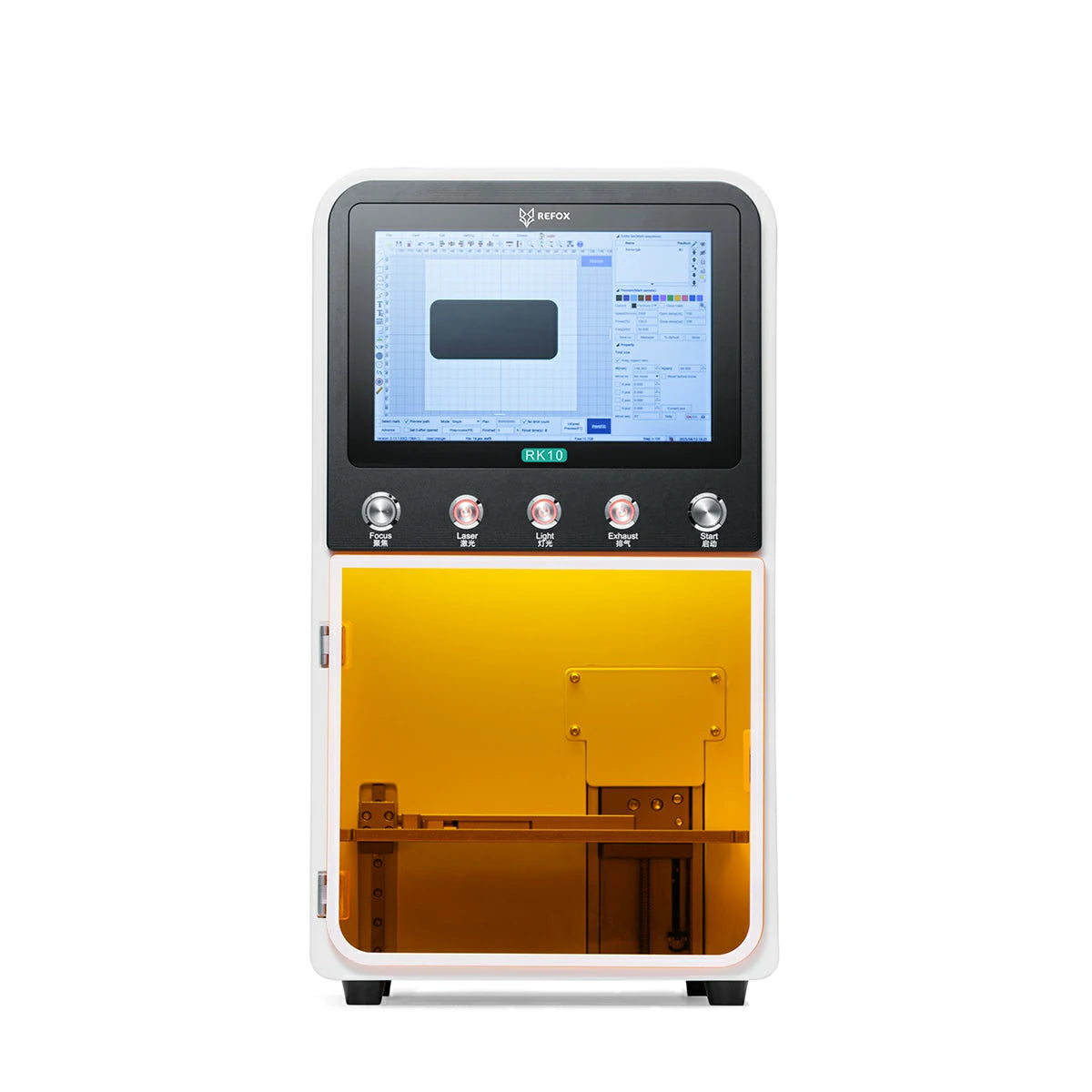

REFOX RK10 Cold Light UV Laser Marking Machine

The REFOX RK10 Cold Light UV Laser Marking Machine revolutionizes phone repair with advanced cold light UV laser technology that safely separates back glass and marks materials without heat damage. This professional-grade system delivers precision results while protecting sensitive internal components.

Built-in operating system with extensive model library

OTA updates for up-to-date templates for hundreds of devices

Supports laser marking on diverse materials including plastics, metals, wood, and leather

Unlocks expanded business opportunities beyond phone repair

If you have any questions, you are always welcome to contact us. We'll get back to you as soon as possible, within 24 hours on weekdays.

-

Shipping Information

Use this text to answer questions in as much detail as possible for your customers.

-

Customer Support

Use this text to answer questions in as much detail as possible for your customers.

-

FAQ’s

Use this text to answer questions in as much detail as possible for your customers.

-

Contact Us

Use this text to answer questions in as much detail as possible for your customers.

Expand Business

A next-generation UV cold light laser marking machine designed for professional mobile phone repairs and precision marking. Utilizing a UV cold light source, it ensures safe and precise adhesive softening for front glass OCA, back covers, and screen brackets, eliminating the risk of burning or damaging sensitive components.

Advanced Features

Next-generation phone repair technology with our UV laser system

2-Minute Glass Separation

Cold Light UV Laser Marking Machine

Key Benefits of REFOX RK10

Discover why professionals choose our cold light UV laser technology over traditional methods.

Screen Safety Guaranteed

Our cold light UV laser precisely targets adhesives without damaging sensitive screen components, keeping displays perfectly intact.

Screen Damage Risk

Traditional red lasers often damage screens during repair, causing costly replacements and unhappy customers.

Zero Burn Technology

The cold light process eliminates heat damage, ensuring materials like wood, paper, and delicate plastics remain unburned and pristine.

Burn Damage Common

The heat from red lasers frequently burns materials, limiting their applications and damaging workpiece integrity.

Advanced Features

Engineered for precision, safety, and efficiency

Cold Light Technology

UV cold light source prevents heat damage to sensitive components during repair operations.

OTA Updates

Regular over-the-air updates keep your device library current with the latest phone models.

One-Button Operation

Simplified automation with wireless keyboard and mouse for effortless operation.

Auto-Focus System

Photoelectric sensing enables automatic laser focusing with a single click.

Safety Protection

Built-in smoke extraction and UV-blocking cover ensure safe operation.

Multi-Language Support

Available in 16+ languages including English, Spanish, Arabic, Chinese, and more.

RK10 vs LM80B

Choose the perfect one for you

Laser Type

UV Laser

Laser Type

Infrared Laser

Wavelength

355 nm

Wavelength

1064 nm

Process Type

Photochemical / Cold Marking

Process Type

Thermal Process

Heat Level

Low

Heat Level

High

Laser Power

5W

Laser Power

6W

Precision

Very High

Precision

Moderate

Damage Risk

Minimal

Damage Risk

Higher (risk to LCD/OLED)

Front Glass Separation

2–3 min

Front Glass Separation

N/A

Bezel Removal

20 s

Bezel Removal

N/A

Middle Frame Removal

30 s

Middle Frame Removal

N/A

Back Glass Removal

7–8 min

Back Glass Removal

2–3 min

Material Compatibility

Plastics, Ceramics, Glass, Paper, Leather, Resin, Metals

Material Compatibility

Metals, Wood

Best For

Delicate disassembly & marking

Best For

Fast marking & heat-resistant materials

Specifications

General Info

- Model: RK10

- Laser Type: UV Cold Light Laser

- Cooling Method: Air-cooled

- Lifespan: >10000 H

- File Formats: JPG/JPEG/BMP/PNG, PLT/DXF

- Spot Shape: Round

Electrical Info

- Voltage: 110V/220V

- Power: ≤500W

- Laser Power: 5W

- Wavelength: 355 nm

Dimensional Details

- Working Area: 180*180 mm

- Screen Size: 215*135 mm

- Marking Line Width: 0.05-0.1 mm

- Marking Depth: 0.015-0.5 mm

- Marking Precision: 0.01 mm

- Marking Speed: ≤10000 mm/s

- Max. Marking Height: 65 mm

- Product Size: 406*304*543 mm

- Package Size: 510*420*710 mm

- Net Weight: 27 kg

- Gross Weight: 37 kg

FAQs

What are the main uses of the UV laser machine?

The REFOX RK10 is primarily used for screen front glass separation, bezel adhesive removal for screen disassembly, bracket adhesive removal, back glass removal, and various engraving tasks on materials like metal, plastic, glass, and leather.

Which models' screen front glass can it separate?

It can separate the original screen front glass of iPhone 13 series and newer models. This limitation is due to the specific OCA glue material used in these screens. Important: Screens that have had their front glass replaced should not be processed with the UV laser machine, as the OCA glue used may not be original.

Is it safe for the screen when separating the front glass?

Yes, the machine's built-in drawings are preconfigured with optimal laser parameters to prevent excessive power from damaging the screen's polarizer or other components. In most cases, no adjustments are needed.

What is the difference between a UV laser machine and a red-light laser machine?

The UV laser generates a shorter wavelength, high-energy beam that is more easily absorbed by surface materials. This results in a smaller heat-affected zone, minimal heat diffusion, and higher precision without damaging areas outside the print zone, unlike red laser machines which carry a higher risk of burning components.

What is the warranty period for the UV laser machine?

The REFOX RK10 comes with a 13-month warranty.